In the realm of sustainable agriculture and biomass utilization, straw dryers have become indispensable for effectively harnessing the energy potential of straw. These specialized machines incorporate cutting-edge technologies and features designed to optimize drying efficiency, ensure product quality, and promote environmental sustainability. Let’s explore the remarkable features of straw dryers and their benefits across various applications.

Robust and Efficient Drying Systems

Straw dryers are equipped with robust drying systems tailored to handle the unique characteristics of straw:

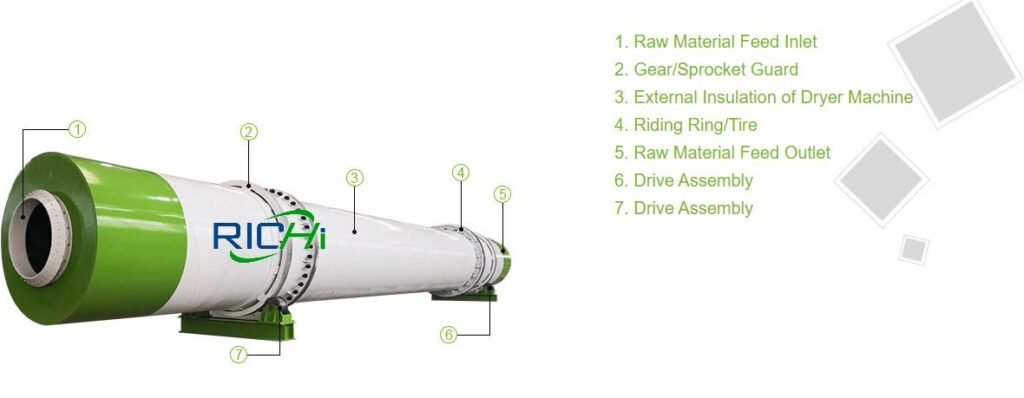

- Rotary Drum Dryers: Ideal for large volumes of straw, these systems offer continuous and uniform drying by rotating the drum to ensure thorough exposure to heated air.

- Belt Conveyor Dryers: Suitable for smaller-scale operations, these dryers gently convey straw through heated zones to gradually reduce moisture content while minimizing material degradation.

Both technologies optimize energy efficiency, minimize heat loss, and reduce operational costs, contributing to sustainable practices in biomass processing.

Advanced Temperature and Moisture Control

Precise control over temperature and moisture levels is critical for effective drying:

- Control Systems: Incorporate PLCs and HMIs for real-time monitoring and adjustment of drying parameters such as temperature profiles, airflow rates, and moisture targets.

- Moisture Sensing Technologies: Utilize NIR or microwave sensors for accurate and continuous moisture measurements, enhancing process control and ensuring consistent product quality.

These advanced features enable efficient drying cycles, minimize energy waste, and support optimal product outcomes.

Efficient Material Handling and Integration

Seamless integration with existing material handling systems ensures smooth operation:

- Conveyor Systems: Integrated within dryers to facilitate loading and unloading of straw, optimizing material flow and operational efficiency.

- Modular Configurations: Designed to scale easily within biomass processing lines, offering flexibility for future expansions or reconfigurations as production needs evolve.

Such designs minimize disruptions, enhance throughput, and support sustainable growth in biomass utilization.

Related post:https://www.richipelletmachine.com/straw-pellet-plant/

Energy-Efficient and Sustainable Design

Straw dryers prioritize energy efficiency and environmental stewardship:

- Heat Recovery Systems: Capture and recycle waste heat to reduce overall energy consumption and greenhouse gas emissions.

- Integration with Renewable Energy: Compatible with biomass boilers or solar thermal systems, further decreasing reliance on fossil fuels and promoting sustainable energy practices.

Additionally, durable construction materials ensure longevity and recyclability, aligning with sustainable manufacturing principles.

User-Friendly Controls and Automation

Designed for ease of use and operational efficiency:

- Intuitive Interfaces: Touchscreen controls or panels provide user-friendly navigation and real-time monitoring of key drying parameters.

- Automation Features: Automatically adjust drying processes based on real-time data, optimizing productivity, reducing downtime, and enhancing operator safety.

These features simplify operation, improve productivity, and uphold safety standards across diverse user environments.

Modular and Scalable Designs

Adaptable to varying production demands and facility requirements:

- Customizable Configurations: Offer different drying capacities, material handling options, and auxiliary components to suit specific operational needs.

- Scalability: Facilitates seamless upgrades or expansions, minimizing capital investments and ensuring long-term operational efficiency.

This modular approach supports flexibility and responsiveness to market dynamics and growth opportunities.

Comprehensive Monitoring and Quality Control

Ensuring product quality and compliance with industry standards:

- Advanced Monitoring Systems: Incorporate sensors and probes for continuous monitoring of critical parameters such as temperature, moisture levels, and product quality.

- Quality Assurance: Integrated sampling and testing capabilities enable real-time analysis to maintain high standards of product quality and safety.

These measures uphold regulatory compliance and customer expectations, fostering trust and reliability in biomass product markets.

Conclusion

As global initiatives promote sustainable agriculture and renewable energy sources, the role of innovative straw dryers becomes increasingly vital. By investing in these advanced technologies, farmers, biomass processors, and environmentally conscious individuals can capitalize on biomass energy markets while supporting resource efficiency and environmental sustainability. Straw dryers equipped with these innovative features not only enhance operational efficiencies but also pave the way for a more sustainable future in biomass utilization and energy production.

For details please contact: Richi manufacture

WhatsApp:86 138 3838 9622

Email:enquiry@richipelletmachine.com