A Ring Die Feed Pellet Machine is an advanced piece of equipment that plays a crucial role in the feed industry. This machine is specifically designed to transform powdered raw materials into uniform pellet forms, meeting the nutritional requirements essential for various types of animal feed.

The process begins with the raw materials entering the ring die pellet machine, where they undergo a meticulous conversion process involving heat, pressure, and moisture to produce high-quality feed pellets.

One of the primary features that define the ring die pellet mill is its vertically-arranged ring die. This unique design element ensures efficient pellet formation as materials are forced through the die holes under high pressure.

The employment of heat and moisture further aids in gelatinizing the starches within the raw components, promoting a cohesive bond in the final pellet product. This combination results in pellets that are durable, have consistent quality, and maintain their structural integrity during handling and storage.

The ring die feed pellet machine is celebrated for its exceptional production capacity. It can handle large volumes of raw materials and convert them into pellets at an impressive rate, making it ideal for large-scale feed production operations.

This high capacity does not come at the expense of consistent pellet quality. The precision engineering of the machine ensures uniformity in each pellet, making sure that the nutritional value remains consistent across the board, which is vital for the health and growth of the animals consuming the feed.

Durability is another hallmark of the ring die pellet machine. Constructed with robust materials and components, it can withstand the rigorous demands of continuous operation, thereby offering a prolonged service life. This attribute not only underscores its reliability but also translates into cost savings over time, as the need for frequent maintenance and component replacement is significantly reduced.

In summary, the ring die feed pellet machine stands out in the feed processing industry for its ability to produce high-quality, consistent, and durable feed pellets efficiently. Its advanced design and reliable performance make it an indispensable asset for any feed manufacturing operation.

When considering investment in feed production equipment, the benefits of a ring die feed pellet machine stand out prominently. Foremost among these advantages is the high efficiency that these machines offer. Thanks to their design, ring die pellet machines ensure enhanced production rates and energy efficiency, optimizing operational throughput compared to other types of pellet machines.

This efficiency translates to higher yields and reduced energy costs, making it an attractive option for feed producers looking to maximize return on investment.

Additionally, one of the noteworthy advantages of a ring die pellet machine is the consistent pellet quality it produces. The design of the ring die ensures uniform pellet size and quality, which is crucial for stable animal diet formulations. Such consistency is essential for meeting nutritional standards and ensuring the health and growth of livestock.

The reliability in pellet quality offered by these machines directly contributes to improved feed performance and animal productivity.

Durability is another key benefit associated with ring die pellet mills. Constructed with robust materials and designed to withstand rigorous operational conditions, these machines offer a long operational life.

Their durability means they require minimal maintenance, reducing downtime and ensuring continuous feed production. This reliability is paramount for feed manufacturers who need dependable equipment for their daily operations.

From a cost-effectiveness perspective, ring die feed pellet machines significantly reduce operational costs. Their high throughput capacity coupled with low wear on components contributes to lower maintenance expenses and reduced need for frequent parts replacements. This cost-saving aspect is crucial for maintaining competitive pricing in the feed market.

Finally, the versatility of ring die pellet machines cannot be overstated. They are suitable for a variety of feed formulations, allowing producers to cater to diverse nutritional requirements. Whether producing feed for poultry, cattle, or aquatic species, the ability to adapt to different ingredients and formulations makes ring die pellet mills an ideal choice for comprehensive feed production operations.

Reasons to Choose a Ring Die Feed Pellet Machine

When considering the production of high-quality animal feed, the ring die feed pellet machine presents numerous compelling advantages. One of the most noteworthy benefits is its ability to produce superior pellet quality, which significantly impacts feed conversion rates and animal growth.

The consistent pressure applied by the ring die during the pelletizing process ensures that each pellet is dense, uniform, and highly nutritious, making it an ideal choice for achieving optimal animal performance.

Another significant factor is the high production capability of the ring die pellet machine. Designed to handle large volumes of feed, this equipment can produce substantial quantities in a shorter amount of time compared to other pellet mills.

This not only boosts productivity but also meets the demands of larger livestock operations, where continuous feed supply is critical. The efficiency of this machine ensures that production targets are met with ease, accommodating both small and large-scale feed requirements.

Operational costs are a critical consideration in any production process, and the ring die pellet mill excels in this regard. It is engineered to minimize energy consumption, leading to reduced overall production costs. The design incorporates features that enhance energy efficiency and lower electricity usage, ensuring that operating costs remain manageable while maintaining high production output.

Maintaining machinery is often a concern for producers, but the ring die pellet machine is designed with ease of maintenance in mind. Key components are accessible, allowing for quick servicing and replacement of wear parts. This results in reduced downtime and prolongs the lifespan of the machine, which is crucial for continuous operation and cost efficiency.

Versatility is another hallmark of the ring die feed pellet mill. It can process a wide range of feed types and ingredient variations, adapting to different nutritional requirements and preferences. Whether producing feed for poultry, livestock, or aquaculture, this machine offers the flexibility to adjust recipes and pellet sizes, ensuring that diverse dietary needs are met.

Working Principle of a Ring Die Feed Pellet Machine

The working principle of a ring die feed pellet machine is crucial in understanding its efficiency and effectiveness in the production of feed pellets. It involves a series of well-coordinated steps, each contributing to the machine’s overall performance and the quality of the final product.

Firstly, the material intake step begins with raw materials being introduced into the ring die pellet machine via the feeder. This feeder regulates the flow of materials, ensuring they enter the machine at a consistent and manageable rate.

Next, in the conditioning phase, the materials are moistened with steam and thoroughly mixed to achieve a uniform consistency. This process is essential because it enhances the binding properties of the raw materials, making them more amenable to pellet formation.

During the pelleting stage, the conditioned material is forced through the ring die by rollers. This step involves significant compression and heat generation, which transforms the material into compact pellets. The ring die pellet mill’s design ensures that the pelleting occurs uniformly, resulting in high-quality, dense feed pellets.

Once pelleted, the hot pellets need to undergo cooling. This step is vital for hardening the pellets and improving their storage stability. The cooling process reduces the temperature and moisture content of the pellets, thereby preventing mold growth and preserving the nutrients within the feed.

Finally, in the discharge phase, the finished pellets are expelled from the ring die pellet machine. These pellets are now ready for packaging or may undergo further processing depending on their intended use. The seamless execution of each of these steps in a ring die feed pellet machine highlights its importance in the production of consistent and high-quality feed pellets.

Specific Parameters of a Ring Die Pellet Machine

The dimensions of a ring die pellet machine are essential parameters that vary according to its production capacity. Typically, these machines span lengths of 2 to 3 meters, widths from 1 to 2 meters, and heights ranging between 1.5 to 2.5 meters. These dimensions are crucial for determining the space required for installation and operation within a production facility.

Capacity is another critical factor to consider when selecting a ring die feed pellet machine. Depending on the specific model and its design, these machines can produce between 1 to 15 tons of pellets per hour. This variability in capacity allows businesses to choose a pellet machine that aligns with their production goals and scale of operations.

The required power for running a ring die pellet mill is substantial, reflecting the machine’s robust performance capabilities. Motor power specifications can range from 37 kW to as high as 250 kW, signifying the need for an adequate and stable power supply to ensure consistent operation. The choice of motor power should match the desired output to optimize efficiency and performance.

Pellet diameter production is also a versatile feature of these machines. A ring die pellet machine can produce pellets with diameters ranging from 2 mm to 12 mm. This flexibility in pellet size caters to various applications and requirements, ensuring that the produced feed pellets meet specific industry standards and animal nutrition needs.

Understanding these specific parameters enhances the decision-making process when selecting a ring die pellet machine, ensuring that it meets the operational requirements and production goals of the business. These machines, with their varying dimensions, capacities, power requirements, and pellet diameter ranges, offer a tailored solution to meet diverse feed production needs.

Suitable Customers for Ring Die Feed Pellet Machines

Ring die feed pellet machines are indispensable for large-scale feed manufacturers, as they are designed to handle high volume production. These machines are capable of producing substantial quantities of feed with remarkable consistency, making them ideal for companies that need to maintain a steady supply of products to their clients.

With their ability to produce uniform pellets at a rapid pace, ring die pellet machines are essential for meeting both demand and maintaining the quality standards expected in the feed industry.

Additionally, livestock farmers represent a significant customer base for ring die pellet machines. Farmers who manage substantial herds require a reliable solution for providing their animals with consistent, high-quality feed.

The uniformity and efficiency of ring die pellet mills ensure that each pellet meets the stringent nutritional requirements vital for animal health and growth. These machines allow farmers to produce feed on-site, mitigating the reliance on third-party suppliers and reducing overall costs.

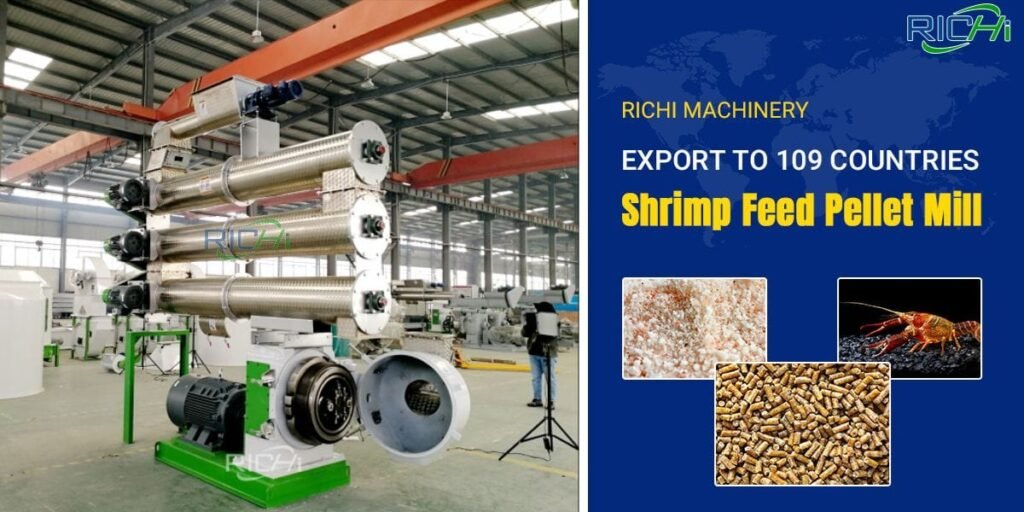

Aquaculture businesses also benefit greatly from utilizing ring die pellet machines. The specialized design of these machines enables the production of specific pellet types suited for various aquatic species.

The ability to customize pellet formulations ensures that the nutritional needs of fish and other aquatic organisms are met, enhancing growth rates and maintaining the health of stock. High durability and consistent performance make these machines essential for aquaculture enterprises focusing on precision and quality in feed production.

Agricultural cooperatives, which often supply feed to an extensive network of member farmers, find ring die feed pellet machines advantageous. By establishing in-house feed manufacturing capabilities, cooperatives can produce high-quality feed in bulk, reducing dependency on external suppliers.

This not only ensures a stable feed supply chain but also offers economic benefits, as producing feed internally is typically more cost-effective. The efficiency and reliability of ring die pellet mills make them a strategic investment for cooperatives aiming to support their members effectively.

Why Choose Richi Machinery as Your Supplier?

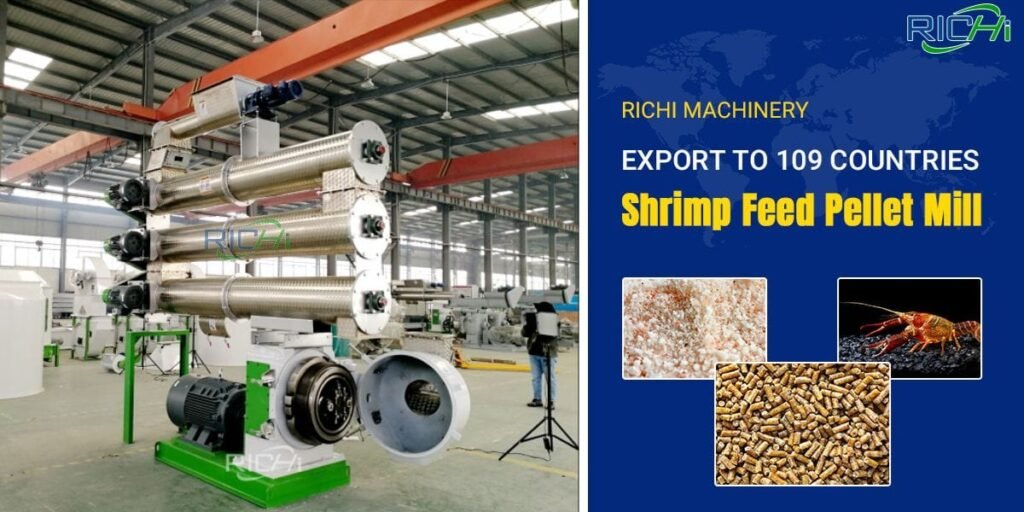

When it comes to selecting a reliable supplier for ring die feed pellet machines, Richi Machinery stands out for several compelling reasons. One of the most critical factors that sets Richi Machinery apart is their commitment to quality assurance.

The company is highly regarded for its high-quality manufacturing processes and the unparalleled reliability of its machines. Each ring die pellet machine undergoes stringent quality control measures to ensure that it meets industry standards and exceeds customer expectations.

In addition to quality assurance, Richi Machinery excels in providing customized solutions tailored to the specific needs of their clients. Whether you are looking for a ring die pellet mill designed for large-scale industrial operations or a smaller machine for niche applications, Richi Machinery has the expertise to deliver a product that fits your specific production requirements.

This customization extends to various parameters such as capacity, material, and operational features, ensuring that each machine perfectly aligns with the customer’s unique needs.

An often-overlooked aspect of choosing a supplier is the after-sales service. Richi Machinery offers excellent after-sales support and maintenance services, ensuring that you receive comprehensive help even after the purchase is complete. Their dedicated support team is always ready to address any concerns, provide maintenance advice, and ensure that your ring die feed pellet machine operates at its optimal performance.

Richi Machinery utilizes advanced technology in the design and manufacturing of their ring die pellet machines. This focus on state-of-the-art technology results in machines that are highly efficient and durable, capable of performing under various conditions with minimal downtime. The integration of cutting-edge technology ensures that these machines offer superior performance and long-term reliability.

Finally, the extensive industry experience that Richi Machinery possesses gives them a considerable edge in the marketplace. With years of specialized expertise in the feed machinery industry, they bring a depth of knowledge and hands-on experience that informs every aspect of their operations. This robust industry experience ensures that they understand the complexities and nuances of the market, enabling them to offer solutions that are both innovative and practical.

Conclusion

The complexities and benefits associated with ring die feed pellet machines underscore their critical role in modern feed production. These machines not only provide high efficiency but also enhance feed consistency, ultimately contributing to better livestock nutrition.

Our discussion outlined the meticulous working principles of the ring die pellet machine, highlighting its robust design and operational capabilities. As noted, one of the standout features is the uniformity and stability in pellet quality these machines deliver, which is especially vital for meeting market demands and adhering to nutritional standards for different animals.

Choosing a reputable supplier is paramount to leveraging the full advantages of ring die feed pellet machines. Richi Machinery, for instance, exemplifies industry standards with innovative technologies, durable machinery, and unparalleled customer support.

Their machines are designed to maximize output while minimizing downtime, ensuring that your production line runs smoothly and efficiently. The quality of service and machinery provided by a supplier like Richi Machinery can greatly influence your overall operational success and economic returns.

When evaluating your specific needs, it is essential to consider the specific properties of the feed you intend to produce and the scale of your operations. Investing in a ring die pellet mill tailored to your requirements ensures optimized production, reduced waste, and ultimately, cost savings.

For businesses looking to enhance feed production efficiency and quality, the integration of a ring die feed pellet machine stands out as a valuable investment. Making informed choices based on a thorough evaluation of machinery options and supplier reliability will yield significant long-term benefits for your feed production operations.