Introduction to Animal Feed Pellet Production Lines

Animal feed pellet production lines play a crucial role in the agriculture and livestock industries. These lines facilitate the efficient production of feed pellets, which are essential for the growth, health, and productivity of livestock and poultry. By converting raw feed materials into uniform pellets, these production lines ensure that animals receive a balanced diet, which can enhance their overall well-being and output.

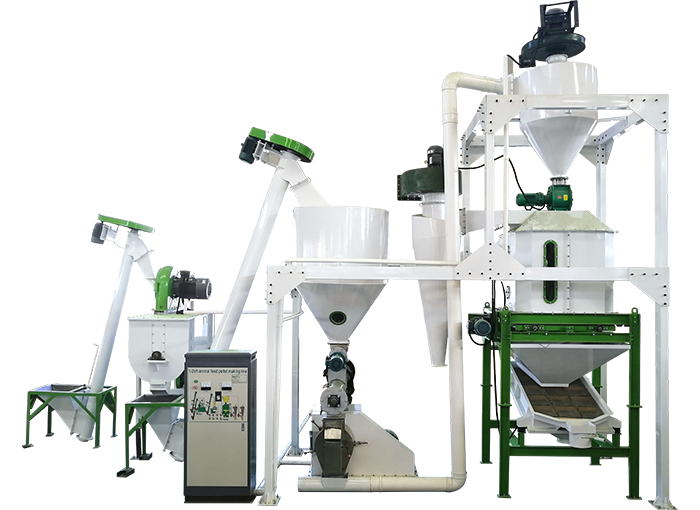

Particularly, the 1-2t/h animal feed pellet production lines are tailored to meet the demands of small to medium-scale operations. These capacities are ideal for farmers and feed manufacturers who require moderate production volumes, ensuring a steady supply of high-quality feed without the need for large-scale industrial equipment. A well-designed production line can include various stages such as grinding, mixing, conditioning, pelleting, and cooling, each contributing to the refinement and quality of the final product.

Efficiency in the production process is not only beneficial for meeting the nutritional needs of the animals but also for optimizing resources and reducing operational costs. Selecting the right manufacturer for a 1-2t/h animal feed pellet production line is critical in achieving these goals. A reputable manufacturer ensures that the equipment is of high quality, operates efficiently, and requires minimal maintenance. Moreover, they provide essential support and guidance throughout the purchasing and installation processes.

The importance of choosing a reliable manufacturer cannot be overstated. A trusted supplier like Richi Machinery stands out due to their expertise and commitment to quality, which can significantly impact the performance of the production line and, ultimately, the success of the agricultural or livestock enterprise. Therefore, thorough research and careful consideration are paramount when investing in an animal feed pellet production line to ensure operational efficiency and superior product quality.

When selecting a manufacturer for a 1-2t/h animal feed pellet production line, several pivotal factors must be considered to ensure efficiency and long-term success. The first criterion is the manufacturer’s experience. A company with extensive experience in the field is more likely to provide quality machinery that has been refined over time through continuous improvement and feedback. Furthermore, an experienced manufacturer will possess in-depth industry knowledge, enabling them to anticipate and mitigate potential challenges in the production process.

Technological capabilities are another critical consideration. The manufacturer should employ advanced technology in their machinery to enhance productivity, reliability, and ease of use. Cutting-edge technology often translates to improved pellet quality and operational efficiency. Ensure that the manufacturer’s production line innovations align with your specific needs, including the ability to handle various raw materials and produce consistent pellet sizes.

Equally important is the level of customer support and after-sales service. A reputable manufacturer should offer robust support throughout the purchase and implementation phases. This includes technical training, installation assistance, and ongoing maintenance services. After-sales service ensures that any operational issues are promptly addressed, minimizing downtime and maintaining production continuity.

Cost considerations cannot be overlooked. While it is crucial to avoid compromises on quality, a comprehensive cost-benefit analysis should be conducted. This involves examining the initial investment versus long-term operational costs, such as energy efficiency and maintenance requirements. It’s essential to choose a manufacturer that offers competitive pricing without sacrificing machine quality and performance.

Lastly, assessing the quality of the machinery itself is paramount. High-quality machines are designed and built to withstand rigorous operational demands, ensuring consistent performance and longevity. Opting for a reputable and reliable supplier mitigates the risk of frequent breakdowns and costly repairs, which can severely impact productivity. By addressing these key factors – experience, technology, customer support, cost, and machine quality – businesses can make a well-informed decision when choosing a manufacturer for their animal feed pellet production line, ultimately fostering operational excellence and sustainability.

Specific Processes in a 1-2t/h Animal Feed Pellet Production Line

The production of animal feed pellets at a 1-2t/h scale involves several critical processes, each contributing to the overall efficiency and quality of the final product. Understanding these stages can help manufacturers optimize their operations and achieve superior outcomes.

The first stage in the animal feed pellet production line is raw material receiving. Raw materials such as corn, wheat, soybean meal, and other additives are delivered and stored. Proper handling and storage are crucial to maintaining the quality and consistency of the feed ingredients.

Next is the grinding process, where the raw materials are finely ground into smaller particles. This step is important because it ensures uniform particle size, which is necessary for optimal pellet formation. Grinding also facilitates better mixing and enhances the digestibility of the feed for animals.

Following grinding is the batching and mixing stage. During this phase, the ground materials are accurately measured and mixed with other ingredients to achieve the desired nutritional balance. Efficient mixing guarantees that each pellet contains a consistent nutrient profile, which is essential for the health and growth of livestock.

The pelletizing process is the core of the production line where the mixed ingredients are compressed into pellets. This is achieved through a pellet mill, which applies heat and pressure to form compact and durable pellets. The quality of pelletizing significantly impacts the integrity and final quality of the feed pellets.

After pelletizing, the hot and moist pellets undergo cooling to reduce their temperature and moisture content. This is necessary to harden the pellets and prepare them for storage and handling. Proper cooling also prevents spoilage and extends the shelf life of the feed.

The cooled pellets then move through screening to remove fines and broken pellets. This step ensures that only uniform and intact pellets proceed to the final packaging stage, enhancing the overall quality and marketability of the feed.

The production line concludes with packaging, where the finished feed pellets are accurately weighed and packed into bags or bulk containers. Proper packaging is vital for protecting the pellets during transportation and storage, as well as for maintaining their nutritional value until they reach the end consumer.

Each of these processes in the 1-2t/h animal feed pellet production line is designed to maximize efficiency and product quality, ensuring that the final feed meets the nutritional needs of various animal species.

Critical Considerations for Quality and Efficiency

Maintaining quality and efficiency in a 1-2t/h animal feed pellet production line necessitates careful attention to several critical factors. Firstly, the quality of raw materials is paramount. Utilizing high-grade ingredients ensures the nutritional value and palatability of the feed, which directly influences the health and productivity of the livestock. Consistent sourcing from reputable suppliers and regular testing of raw materials can help mitigate the risks of contamination or nutritional imbalances.

Secondly, the maintenance of machinery plays a crucial role. Regular servicing and timely replacement of worn-out parts can prevent unexpected downtimes and enhance the longevity of the equipment. Proper lubrication, alignment, and calibration of the machinery are essential practices to maintain its operational efficiency. Additionally, investing in advanced technology that offers real-time monitoring and diagnostics can provide invaluable insights into the performance of the animal feed pellet production line.

Operational training for staff is another vital consideration. Skilled operators who are well-versed in the complexities of the production process can identify and rectify issues promptly, thereby minimizing disruptions. Continuous training programs that focus on the latest industry practices and safety protocols can greatly improve workforce competence and productivity.

Compliance with industry standards is non-negotiable. Adherence to regulatory guidelines not only ensures the safety and quality of the feed but also fosters trust among customers and stakeholders. Regular audits and certifications from recognized bodies can serve as endorsements of the production line’s credibility and reliability.

Lastly, periodic performance audits are essential to assess the overall effectiveness of the production line. These evaluations can identify potential bottlenecks, inefficiencies, or areas for improvement. Implementing the recommendations from these audits can lead to optimized production processes and reduced operational costs.

The correlation between vigilant management and the optimized performance of a 1-2t/h animal feed pellet production line is undeniable. By meticulously addressing these critical considerations, manufacturers can achieve a balance of quality and efficiency that meets the demands of modern livestock farming.

Why Choose Richi Machinery

Richi Machinery https://www.richimanufacture.com/ has firmly established itself as a preferred manufacturer in the realm of 1-2t/h animal feed pellet production lines, underscored by a robust history, unmatched expertise, and a stellar market reputation. Founded several decades ago, Richi Machinery has continuously evolved, aligning with technological advancements and market demands to position itself as a frontrunner in the industry.

One of the key factors that set Richi Machinery apart is its profound expertise in the development and manufacturing of animal feed pellet production lines. Their engineering teams are composed of seasoned professionals who bring a wealth of knowledge and precision to the design and manufacturing process. This ensures that every production line they deliver meets the highest quality standards and performance metrics.

In addition to technical expertise, Richi Machinery is highly regarded for its customer-centric approach. The company places immense importance on understanding and addressing the specific needs and challenges of its clients. This commitment to personalized service is evident in the comprehensive support they offer, from initial consultation and installation to ongoing maintenance and operator training. Their customer service team is accessible and responsive, ensuring that clients receive prompt and effective solutions to their queries and issues.

Innovative technology is at the core of Richi Machinery’s offerings. They continuously invest in research and development to integrate the latest technological advancements into their animal feed pellet production lines. These innovations not only enhance the efficiency and reliability of their machinery but also ensure compliance with safety and environmental standards. For example, their production lines are designed to optimize energy consumption and minimize waste, reflecting their commitment to sustainable practices.

Richi Machinery’s proven track record is another compelling reason for its preferred status among manufacturers of animal feed pellet production lines. Their projects span across various continents, serving a diverse clientele that includes small-scale farmers and large agricultural enterprises. The consistent performance and durability of their equipment have garnered positive testimonials and repeat business from satisfied customers around the globe.

In summary, Richi Machinery’s blend of historical credibility, technological innovation, customer-oriented service, and proven success in the market makes them a leader in the production of 1-2t/h animal feed pellet production lines. Choosing Richi Machinery ensures reliability, quality, and ongoing support, all pivotal for the success and sustainability of any animal feed production endeavor.

Detailed Introduction of Richi Machinery

Richi Machinery stands as a prominent name in the field of animal feed pellet production lines. Specializing in advanced pellet mills and comprehensive feed production equipment, the company offers a wide range of products tailored to meet diverse needs. Their product lineup includes not only high-efficiency pellet mills but also auxiliary machines like mixers, dryers, and coolers, designed to ensure a seamless and efficient production process.

Renowned for their technical innovation and commitment to quality, Richi Machinery has executed several key projects globally, establishing themselves as a reliable partner in the animal feed industry. For instance, the company’s 1-2t/h animal feed pellet production line is exceptionally well-regarded for its precision, efficiency, and durability, making it a preferred choice for feed producers aiming to enhance their operational efficiency.

Richi Machinery’s success is reflected in numerous accolades and certifications that validate their industry standing. They have received ISO9001:2008 certification, ensuring that their quality management systems meet international standards. Additionally, their products comply with CE certification, underscoring their adherence to stringent European safety standards. These certifications not only highlight the company’s commitment to quality but also provide customers with assurance regarding the reliability and safety of their machinery.

Further cementing their industry reputation, Richi Machinery has formed strategic partnerships with key stakeholders across the globe. Collaborations with prominent agricultural and animal husbandry associations have helped them to stay abreast of the latest industry trends and technological advancements. This collaborative approach not only enhances their product offerings but also fosters innovation that benefits their clientele.

Richi Machinery’s dedication to continuous improvement and customer satisfaction is evident in their complete post-sale support system. Offering comprehensive maintenance services, technical support, and operator training sessions, the company ensures that clients can maximize the efficiency and lifespan of their animal feed pellet production line. These factors collectively illustrate why Richi Machinery is a trusted and preferred supplier in the industry.

Richi Machinery’s Market Position and Professionalism

Richi Machinery stands as a prominent player in the animal feed pellet production line industry, both within China and on the global stage. With its extensive experience and expertise in manufacturing feed production machinery, the company has carved out a significant market share, demonstrating its capability to cater to a wide customer base. Their influence in the industry is well-established, underscoring the trust and reliability that customers associate with their products and services.

One of the hallmarks of Richi Machinery’s professional approach is its robust focus on research and development (R&D). By continually investing in cutting-edge technologies and innovative solutions, the company ensures that its animal feed pellet production line remains at the forefront of industry advancements. This dedication to R&D not only enhances the performance and efficiency of their machinery but also adapts to the evolving needs of the market.

Quality control is another area where Richi Machinery excels. The company implements stringent quality assurance protocols to guarantee the reliability and durability of its equipment. From the selection of raw materials to the final inspection stages, every process is meticulously monitored to maintain high standards. This commitment to quality ensures that customers receive superior products that meet their specific requirements and expectations.

Customer engagement is also a key aspect of Richi Machinery’s professionalism. The company places a strong emphasis on building and maintaining long-term relationships with its clients. By providing comprehensive support, including pre-sale consultancy, installation assistance, and after-sales services, Richi Machinery ensures customer satisfaction and trust. This client-centric approach not only fosters loyalty but also reinforces the company’s reputation as a dependable partner in the animal feed production industry.

Richi Machinery’s status as the largest pellet mill manufacturer in Henan, China, further solidifies its credibility. This distinction attests to the company’s extensive capabilities and resources, ensuring prospective buyers of their capacity to deliver high-quality, reliable animal feed pellet production lines. The combination of market leadership, professional excellence, and a robust support system makes Richi Machinery a preferred choice for customers seeking dependable solutions in the feed production sector.

Conclusion

In choosing a manufacturer for your 1-2t/h animal feed pellet production line, it is essential to consider factors that ensure quality, efficiency, and reliability. The right manufacturer can significantly impact the overall productivity and profitability of your feed production operations. An optimal choice will offer advanced technology, durable machinery, excellent customer support, and a solid track record in the industry.

Richi Machinery stands out as an exemplary provider in the field of animal feed pellet production lines. With years of expertise, cutting-edge technology, and a customer-centric approach, Richi Machinery has established itself as a top choice for businesses looking to invest in efficient and robust feed production equipment. Their commitment to quality and innovation ensures that clients receive the best possible solutions tailored to their specific needs.

Richi Machinery’s 1-2t/h animal feed pellet production line is designed to deliver maximum efficiency and superior performance. Their equipment is built with advanced features that optimize production processes while maintaining the highest standards of quality. This ensures not only the durability of the machinery but also the consistent production of high-quality animal feed pellets.

Moreover, Richi Machinery offers comprehensive support and consultation services, making them a reliable partner in your feed production endeavors. Their team is dedicated to providing solutions that meet your specific requirements and help you achieve your production goals.

Considering the significant impact of choosing the right manufacturer for your animal feed pellet production line, it is worth exploring what Richi Machinery has to offer. We encourage you to reach out to Richi Machinery for more information or to schedule a consultation. By partnering with a trusted and innovative company like Richi Machinery, you can ensure the success and efficiency of your feed production operations.