As demand for compact, nutritious livestock feed increases, more farmers and entrepreneurs are turning to alfalfa pellet making machines to process their own forage. However, choosing the right scale of machinery—small-scale vs. large-scale—can be a complex decision that affects productivity, investment, labor, and business growth.

This article dives deep into the key differences between small- and large-scale alfalfa pellet machines, comparing their features, costs, advantages, and ideal use cases. Whether you’re a family farmer or an industrial feed manufacturer, this guide will help you select the best equipment for your needs.

1. Understanding the Basic Function of Alfalfa Pellet Machines

Regardless of scale, the fundamental purpose of an alfalfa pellet machine is to:

- Compress alfalfa (dried and chopped) into uniform cylindrical pellets

- Improve feed digestibility and reduce transport and storage volume

- Ensure nutritional preservation with minimal waste

The main components include:

- Feeder

- Conditioner

- Pelletizing chamber (with rollers and die)

- Cutting system

- Cooling unit (optional)

- Packaging or storage system

Now let’s explore how these components differ by machine size and application.(Related post:Grass Pellet Machine )

2. Small-Scale Alfalfa Pellet Making Machines

A. Key Characteristics

- Capacity: 50–800 kg/h

- Power requirement: 3–22 kW (can be powered by diesel, PTO, or electricity)

- Mobility: Often portable or on small trailers

- Design: Simple structure, easy maintenance

- Pellet size options: 2–8 mm

- Feeding system: Manual or semi-automatic

B. Advantages

- Low investment cost (typically $1,000–$8,000)

- Ideal for on-farm feed processing

- Easy operation and low technical barrier

- Suitable for test batches or specialty feed

- Fits into low-resource environments

C. Limitations

- Limited hourly output

- Fewer automation features

- May require pre-cutting and drying before pelletization

- Less efficient for commercial-scale operations

D. Ideal Users

- Hobby farmers

- Smallholders with up to 100 head of livestock

- Pet feed producers (rabbits, guinea pigs, etc.)

- Co-ops or small agribusinesses

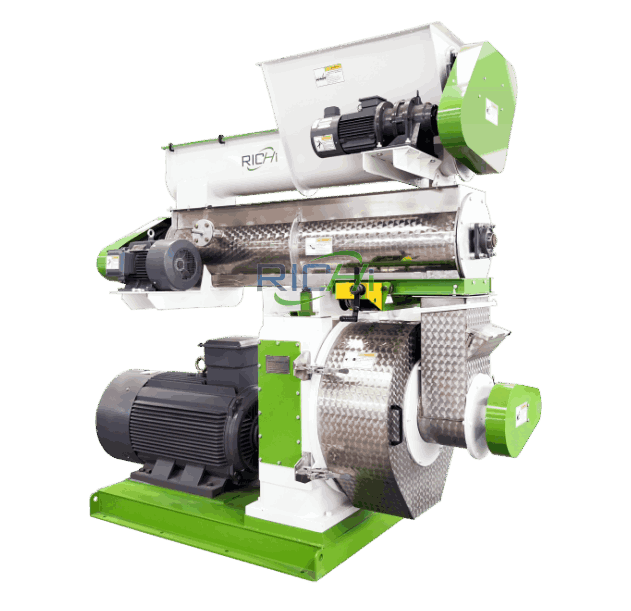

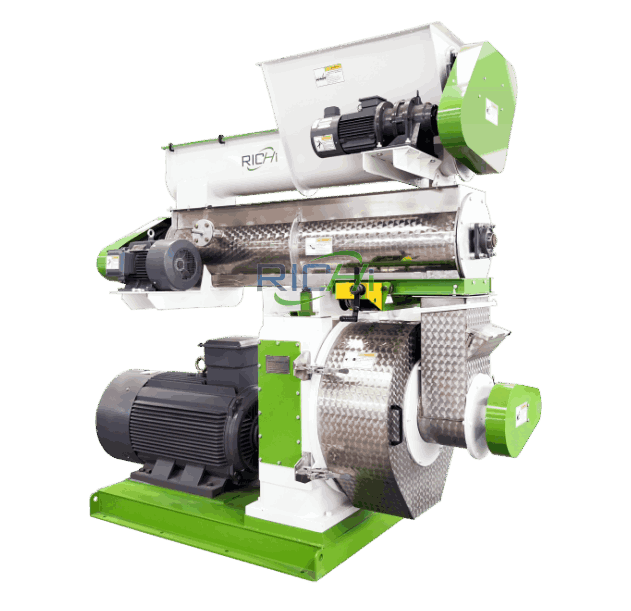

3. Large-Scale Alfalfa Pellet Making Machines

A. Key Characteristics

- Capacity: 1–20 t/h

- Power requirement: 55–500+ kW

- Structure: Stationary or plant-integrated

- Automation level: Fully automatic, with PLC control

- Integrated systems: Crushers, dryers, coolers, screeners, and baggers

B. Advantages

- High throughput, ideal for commercial production

- Labor-saving automation

- Consistent pellet quality with in-line sensors and monitoring

- Often part of a complete production line

C. Limitations

- High capital cost ($30,000–$500,000+)

- Requires technical staff for operation and maintenance

- Needs large floor space and stable electricity supply

D. Ideal Users

- Commercial feed mills

- Alfalfa exporters

- Contract pellet producers

- Agricultural cooperatives with centralized processing

4. Side-by-Side Comparison Table

| Feature | Small-Scale Machine | Large-Scale Machine |

|---|---|---|

| Output | 50–800 kg/h | 1–20 t/h |

| Power Source | Electric, Diesel, PTO | Electric only (3-phase) |

| Automation | Manual/Semi-automatic | Fully automatic with PLC |

| Installation Space | <10 m² | >100 m² |

| Investment | $1,000–$8,000 | $30,000–$500,000+ |

| Labor Requirement | 1–2 persons | 2–6 skilled staff |

| Target User | Farmers, co-ops | Feed companies, exporters |

| Customization Options | Limited | Extensive |

| Typical ROI Time | 6–18 months | 1–3 years |

5. Factors to Consider When Choosing the Scale

a. Production Volume

If you produce a few tons of alfalfa per year for personal use, small-scale is ideal. For bulk processing, a large-scale system is more economical long term.

b. Budget

Small-scale units are affordable with low operating costs, while large-scale systems are a major capital expenditure requiring financing or government support.

c. Labor Availability

Manual machines need more hands-on labor; large systems rely more on skilled operators and maintenance technicians.

d. Market Scope

Producing pellets for your own farm? Small-scale is enough. Selling to distributors or retailers? You’ll need a large-scale system.

e. Space and Infrastructure

Small machines fit in a shed or barn; large lines need concrete floors, ventilation, electrical transformers, and storage facilities.

6. Hybrid Solutions: Mid-Scale Pellet Systems

Some manufacturers now offer modular alfalfa pellet machines that combine the best of both worlds:

- Output of 1–3 t/h

- Partial automation

- Upgradable design (start small, scale later)

- Moderate investment ($10,000–$50,000)

These are ideal for:

- Farmer cooperatives

- Entrepreneurs building a regional feed business

- Alfalfa growers looking to vertically integrate

7. Cost Breakdown Examples

Small-Scale System (~500 kg/h)

- Machine: $4,500

- Crusher: $1,000

- Dryer (solar or electric): $2,500

- Total setup: ~$8,000

Large-Scale System (~10 t/h)

- Pelletizer: $80,000

- Pre-processing line: $60,000

- Dryer: $90,000

- Cooler + bagger: $70,000

- Control system + installation: $50,000

- Total: $350,000+

8. Case Studies

Small-Scale Success: Farmer in Kenya

- Setup: Diesel-powered 300 kg/h pelletizer

- Feeds: Dairy cows, goats

- Results: Saved $3,000 annually by making own feed

Large-Scale Success: US Export Company

- 10 t/h production line in California

- Exports alfalfa pellets to UAE and China

- ROI: Reached in 24 months due to export margins (Related post:10-15T/H Grass Alfalfa Pellet Production Line in Argentina)

9. Common Mistakes to Avoid

- Overbuying capacity: Leads to higher energy use and underutilization

- Neglecting pre-processing needs: Pellet quality suffers without proper chopping and drying

- Ignoring maintenance costs: Especially true for high-output ring die machines

- Underestimating dust control needs: Poor air quality affects both health and machine life

10. Final Recommendations

| Situation | Recommended Machine Type |

|---|---|

| Personal livestock feeding (under 50 cows) | Small-scale flat die pelletizer |

| Community feed project | Mid-scale modular system |

| Commercial feed production | Large-scale industrial pellet line |

| Alfalfa exporter or agribusiness | Fully automated high-capacity setup |

Remember, buying the right-sized machine is not about the biggest output—it’s about aligning with your goals, resources, and market strategy.

Conclusion

Choosing between a small-scale and large-scale alfalfa pellet making machine can define the trajectory of your farming operation or feed business. While small machines offer low-cost, flexible solutions, large systems deliver efficiency and profitability at industrial levels. For many users, a scalable, mid-range setup offers the best balance.

By understanding your unique context and aligning machine scale with your production goals, you can unlock the full benefits of alfalfa pelletization—improved sustainability, profitability, and feed quality.