Organic fertilizer production machines are specifically engineered to convert organic materials into pellets, offering a sustainable and efficient method to recycle waste into valuable agricultural inputs. However, a common inquiry arises: Can these machines also produce chemical fertilizer pellets? This article examines the capabilities of organic fertilizer production machines in processing chemical fertilizers, the differences between organic and chemical fertilizer pelletization, and the associated benefits and challenges.

Understanding Organic Fertilizer Production Machines

Organic fertilizer production machines are primarily designed to handle a variety of organic materials, including:

- Animal Manure: Such as cow, chicken, and pig manure.

- Agricultural Residues: Including straw and crop stalks.

- Forestry Waste: Such as sawdust and wood chips.

- Municipal Solid Waste: Food scraps and green waste.

These machines typically involve several stages: crushing, mixing, granulating, drying, cooling, and packaging. The granulation process is crucial for transforming organic matter into uniform pellets that are easy to manage, store, and apply. (Related post:manure pellet mill)

Differences Between Organic and Chemical Fertilizers

Before exploring the capabilities of organic fertilizer production machines, it’s essential to understand the fundamental differences between organic and chemical fertilizers:

- Composition:

- Organic Fertilizers: Made from natural materials like manure, compost, and plant residues. They release nutrients slowly and enhance soil health by adding organic matter.

- Chemical Fertilizers: Manufactured from synthetic materials, providing specific nutrients (nitrogen, phosphorus, potassium) in readily available forms. They are designed for quick nutrient release.

- Granulation Process:

- Organic Fertilizers: Require a granulation process that accommodates high moisture content and fibrous materials.

- Chemical Fertilizers: Typically involve a different granulation process suitable for dry, powdery materials.

Can Organic Fertilizer Machines Process Chemical Fertilizers?

While organic fertilizer production machines are optimized for organic materials, they can sometimes be adapted to process chemical fertilizers. Here’s how:

- Granulation Compatibility: Some organic fertilizer granulators, such as rotary drum granulators and disc pan pelletizers, can accommodate a variety of materials, including certain types of chemical fertilizers. These machines can produce pellets from dry, powdery substances by incorporating a binding agent or adjusting moisture levels.

- Adjustable Parameters: Many modern organic fertilizer machines come with adjustable parameters. This flexibility allows operators to modify settings like moisture content, feed rate, and granulation speed to accommodate different materials, including chemical fertilizers.

- Dual-Use Machines: Some manufacturers create dual-use machines capable of processing both organic and chemical fertilizers. These machines are designed with features that cater to the specific requirements of both material types, providing versatility for producers.

Benefits of Using Organic Fertilizer Machines for Chemical Fertilizers

- Cost-Effectiveness: Utilizing existing organic fertilizer machines to process chemical fertilizers can be economically advantageous, eliminating the need for separate equipment.

- Versatility: Dual-use machines provide flexibility for producers handling both organic and chemical fertilizers, enabling them to switch between materials as needed.

- Efficiency: Modern organic fertilizer machines are designed for high efficiency, ensuring consistent pellet quality and reducing production time.

Challenges and Considerations

- Material Compatibility: Not all organic fertilizer machines are suitable for processing chemical fertilizers. It is essential to ensure that the machine can handle the specific properties of the chemical fertilizers being processed.

- Adjustments and Modifications: Processing chemical fertilizers may necessitate adjustments to machine settings or modifications to the granulation process, which can incur additional costs and require technical expertise.

- Quality Control: Maintaining consistent pellet quality can be challenging when alternating between organic and chemical materials. Producers must implement strict quality control measures to ensure product consistency. (Related post: organic fertilizer pellet making machine)

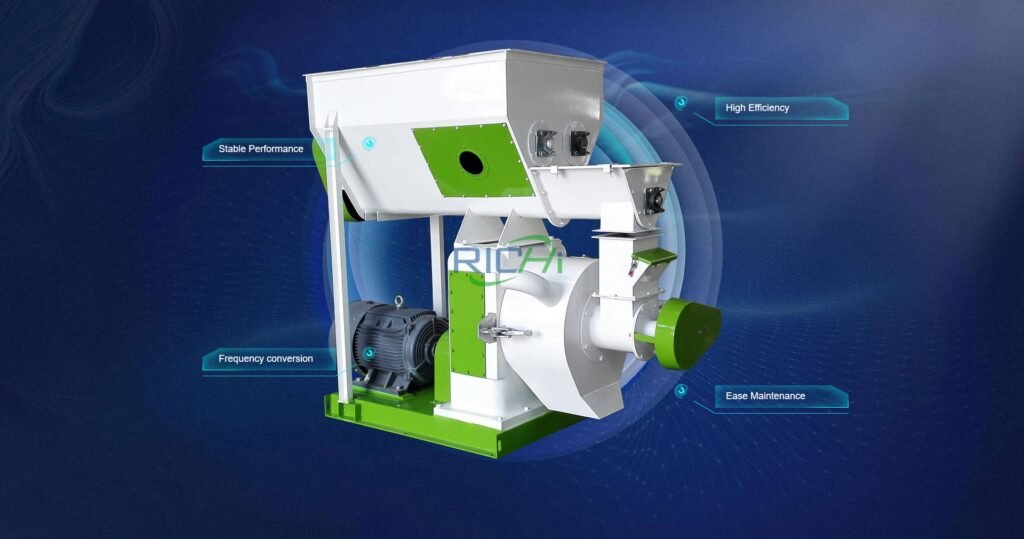

Case Study: RICHI Machinery

RICHI Machinery offers a range of organic fertilizer pellet machines that can be adapted for chemical fertilizer production. Their machines feature:

- Adjustable Granulation Parameters: Allowing for the processing of various materials, including chemical fertilizers.

- High Production Capacity: Ensuring efficient production of large volumes of pellets.

- Stable and Reliable Operation: Minimizing downtime and maintenance requirements.

For example, RICHI’s organic fertilizer granulator can process animal manure, crop straw, and other organic materials, and with appropriate adjustments, it can also handle certain chemical fertilizers.

Conclusion

Although organic fertilizer production machines are primarily designed for organic materials, they can, in some cases, be adapted to process chemical fertilizers into pellets. This versatility presents several benefits, including cost savings, operational efficiency, and flexibility for producers managing multiple types of fertilizers.

However, it is crucial to consider the specific requirements of the chemical fertilizers being processed and ensure that the machine can effectively handle these materials. Adjustments to machine settings and granulation processes may be necessary to achieve optimal results.

Manufacturers like RICHI Machinery provide advanced organic fertilizer pellet machines with adjustable parameters, making them suitable for a broader range of applications. By leveraging the capabilities of these machines, producers can enhance their production processes and meet the diverse needs of the agricultural industry.