Wood pellet machine, additionally determined as a wood pellet press, wood pellet mill, is general in the world. With the growth of biomass energy, there are some various manufacturing abilities to convert biomass into heat as well as electrical energy. The wood pellet equipment is the unique machine to do that.

Wood pellet maker transforms the raw products into high-efficient biomass fuel. The wood pellet machine also provides the possibility to start a business. So, the wood pellet equipment is an increasing number of important for human life and also industry.

It is excellent to locate a trusted wood pellet equipment producer for purchasing the best top quality product for your industry. Below, I’m going to share some vital things about the wood pellet machine that you need to know.

What is Wood Pellet Machine?

A wood pellet machine is a type of pellet machine for handing out resources like sawdust, wood, peanut shell, straw, leaves, and so forth. Today, there are a number of different types of pellet mills on the market.

And the distinct two kinds are level die pellet mills and also ring die pellet mills. The wood pellet mill can treatment numerous raw materials whatever the size allows or otherwise, and also the pellet dimension also can be adapted by the hammer mill.

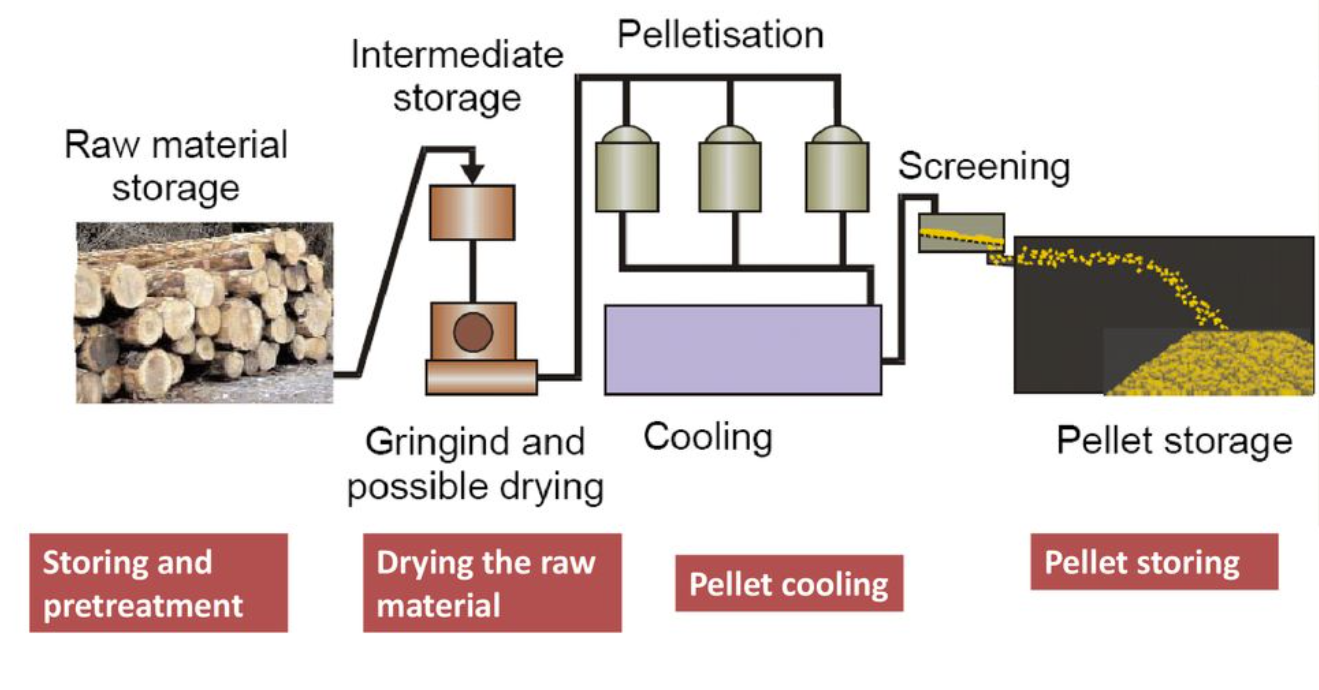

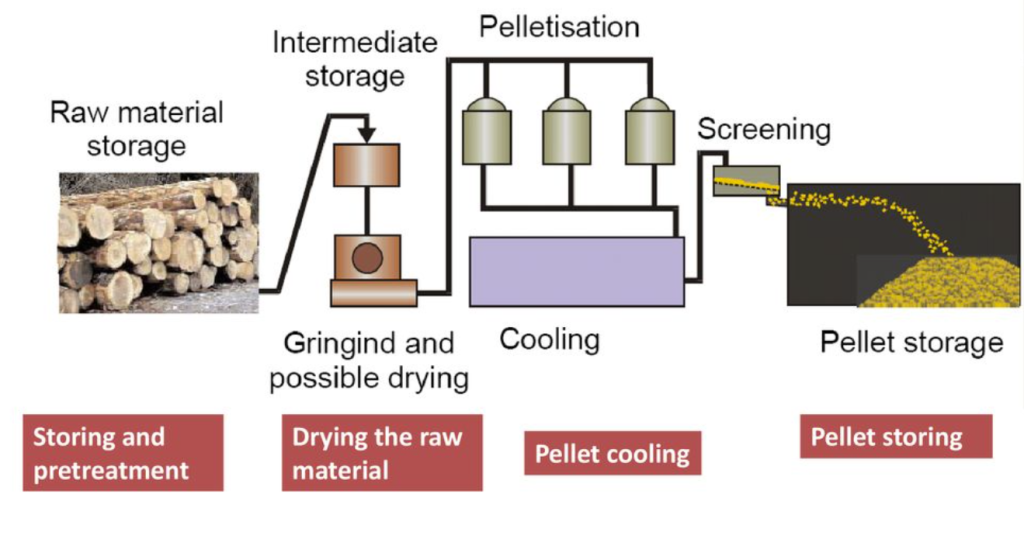

Process of Making Wood Pellet

In industries, the procedure of wood pellets production primarily continues in some groups, including:

Wood Material Crushing

Normally, the dimension of the raw material must be smaller than the pellet size. For wood logs or rounded wood, crushing treatments by a wood crusher are required. Then the lesser wood blocks will be fed into the wood chipper to chip the wood into chips for added usage.

Water Dampness Control

For making the finest wood pellets, the water dampness of the raw material ought to be about 12%. So, it is vital to get rid of extra water from the raw material. In commercial pellets production, a wood pallet colder is normally embraced.

Biomass Pelletizing

Wood product over a feeder enters the pelletizing space, where the die as well as the rollers are indicating relatively at a high speed. With the extrusion strength and also the heat creating in the relative activity, the intermolecular forces in the wood material particle have transformed.

Consequently, the plasticity of the wood material has bigger. Then the products are created into pellets by the hole on the die as well as strapped out.

Wood Pellets Cooling

The pellets derive from the pellet machine are cozy as well as damp. A pellet colder is used for bringing the temperature down as well as decrease the water content. After cooling, they are stiffer and calmer to store or transfer.

Wood Pellets Weighing as well as Packing

A wood pellet packing machine can pack the pellets in bags of a similar weight for carriage or sale. For a huge quantity of wood pellets, mass trucks are called for. Bulk pellets are strained from the pellet mill straight right into trucks for shipment to mass storage space ampules.

These are some crucial things that you need to learn about wood pellets. You can locate a leading wood pellet machine manufacturer for purchasing top notch equipment for your sector.